This method was developed for silica telecom fibers in the 1970s, with pioneering contributions from the University of Southampton (UK), Bell Telephone Laboratories (Bell Labs), and Corning. Many fiber preforms are fabricated with a process called modified chemical vapor deposition (MCVD or just CVD). Vapor Deposition Methods Different variants of deposition processes are used. In this section, the fabrication of standard fiber preforms is explained, while special preforms for various types of specialty fibers are discussed later on.

Here, we cover only the fabrication of glass preforms, and mostly on those for silica fibers. Also, some companies offer to apply the cladding glass to received core rods. However, there are also suppliers of various kinds of fiber preforms, which are then to be drawn into fibers elsewhere.

In most cases, the fiber preforms are fabricated on the same sites where the fiber drawing tower is operated. Plastic optical fibers can be drawn from preforms in a similar process as often used for silica fibers, only with a much lower temperature (e.g. In particular, this holds for the refractive index profile, including the structure made for the fiber core.

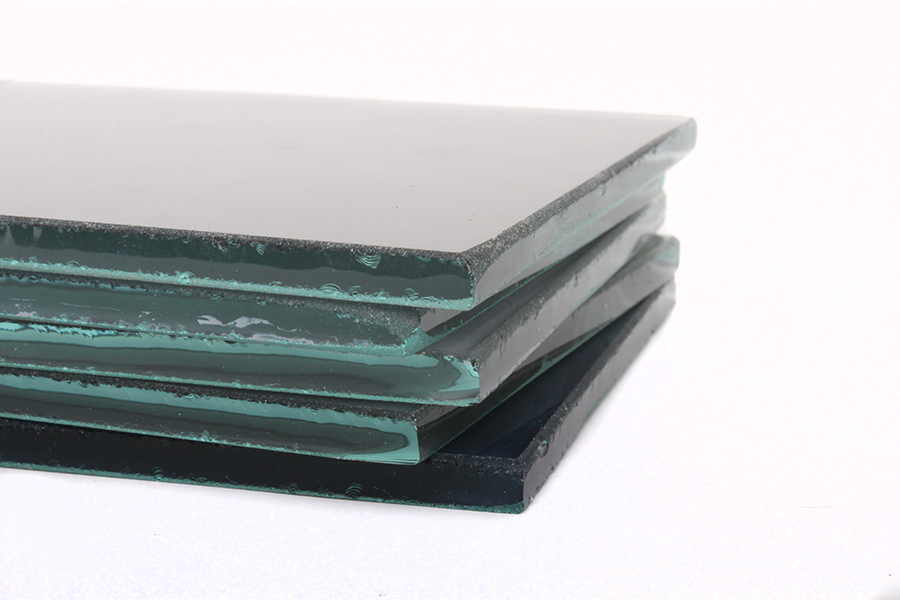

The drawn fiber has a much smaller diameter than the preform, and all features of the preform are getting correspondingly smaller in the fiber. The article on fiber fabrication describes the drawing process and details of the used drawing towers. 40 cm long and have a diameter of a couple of centimeters, but there are also much longer preforms and some with a large diameter of e.g.

#Glass preform how to

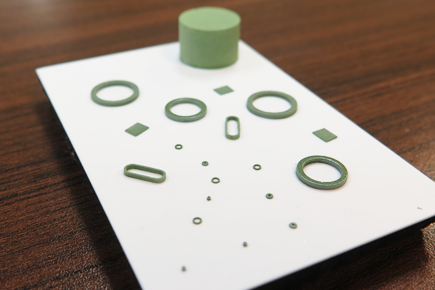

How to cite the article suggest additional literatureĪ fiber preform is a typically cylindrical piece of optical glass which is used for drawing an optical fiber in a fiber drawing tower. Please contact Elan Technology glass manufacturers for more information.Definition: a piece of glass from which an optical fiber can be drawn Elan Technology’s glass ceramic composites also have higher chemical durability, can resist higher temperatures, and can be more easily machined to complex geometries than conventional varieties of glass. The Elan 46 ceramic glass composite has unique properties that allow for the ability to vary the coefficient of thermal expansion and can therefore form hermetic seals with a variety of metals. Because glass is extremely strong in compression, compression seals can withstand very high pressures. Compression sealing takes place when the glass and the metal have different coefficients of thermal expansion and the metal shrinks around the solidified glass. Used for steel or stainless steel housing, nickel iron pins, and barium alkali glass, compression seals can withstand extremely high pressures and physical stress such as mechanical and thermal shock. Matched seals are used for less intensive applications such as light bulbs and electronic packaging. This “matched seal” is the weaker of the two glass-to-metal hermetic seals and cannot resist large differential pressures across the two materials. When the glass and the metal package have the same coefficient of thermal expansion, the seal derives its strength from the chemical bond between the glass and the oxide formed on the metal parts. There are two types of glass-to-metal hermetic seals which vary based upon the properties of the glass and metals used: Matched Seals Glass Recommendations Glass Preforms for Hermetic Sealing Common Problems in Glass-to-Metal Seal Design Types of Glass-to-Metal Seals

0 kommentar(er)

0 kommentar(er)